at least it will have company in the dumpster...

Since Shocky was now sporting spiffy 16V 100 mm drive axles

instead of his stock 90 mm, the old hub carriers were also slated

to go

|

|

|

at least it will have company in the dumpster... Since Shocky was now sporting spiffy 16V 100 mm drive axles instead of his stock 90 mm, the old hub carriers were also slated to go |

|

|

|

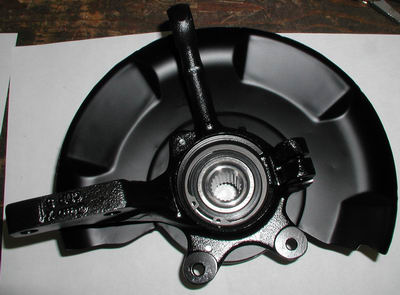

...after the bead blasting and before paint |

|

...a coat or two of engine enamel (low-gloss black) and the dust shields are set out to dry... |

|

....no paint thinner this time since new hubs were on the way |

|

VERY HOT! (did I mention my second love is metal....after Sciroccos of course  ) ) |

|

um...yeah...I hate rust..... |

|

|

|

ahhh....once again....media blaster to the rescue! And here are the old bearings and hubs from the 16V hub carriers..... |

|

|

|

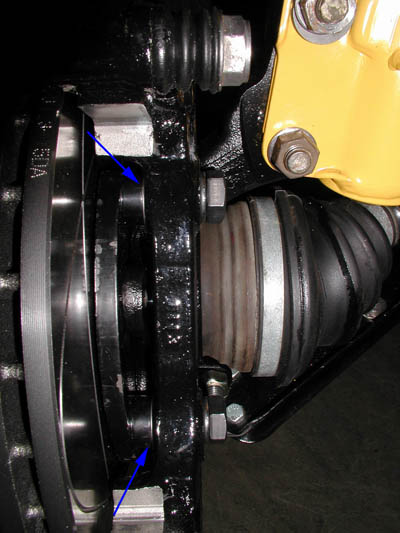

nice smooth edges...and no internal burrs either! |

|

|

|

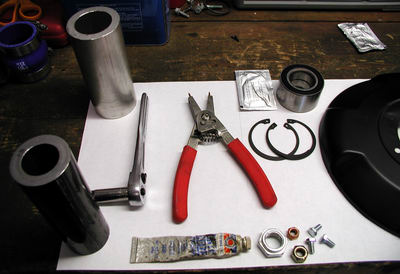

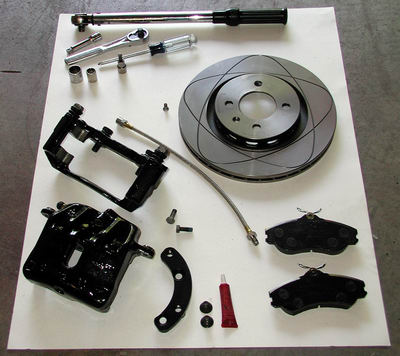

Tubing for pressing in the bearings and other assorted tools and greases.... Wheel bearing, snap rings, dust shield, hub, hub carrier, and assorted hardware.... |

|

|

|

Not too much grease...not too little.... |

|

|

With the bearing already partially in, you can see that having the level hunk o' aluminum really helps press it in evenly... |

|

|

|

|

....stupid snap ring....grrr..... |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

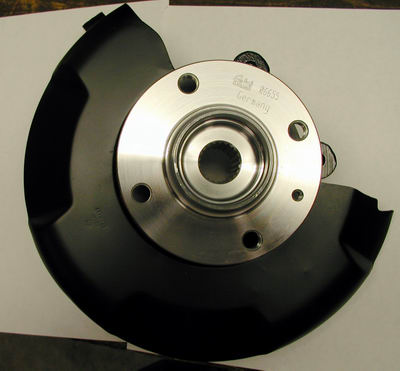

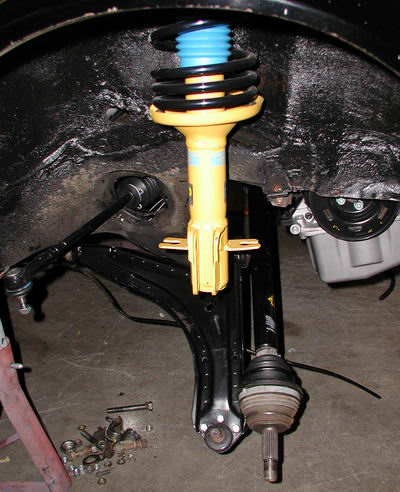

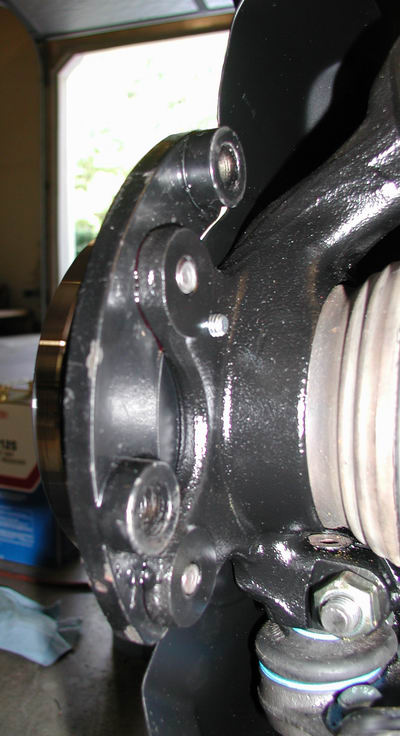

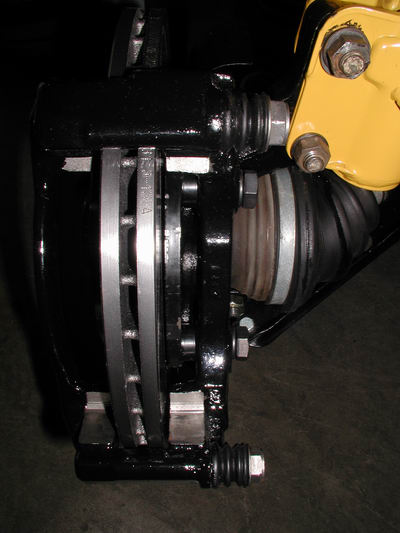

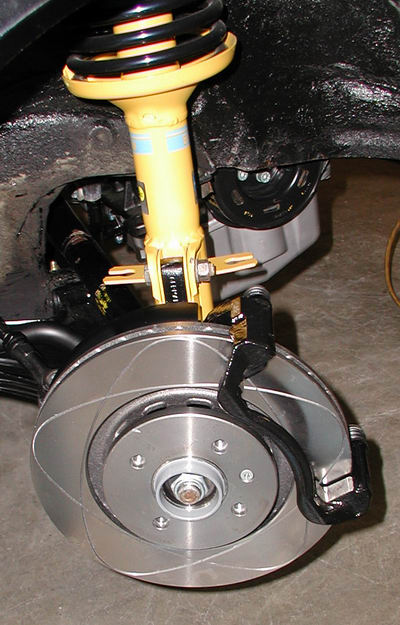

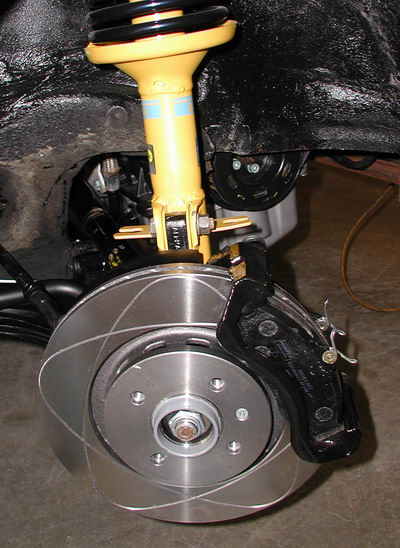

It is a shame that those beautiful hubs are so covered up after install.....but....the whole thing still looks very pornographic... |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PREVIOUS |

INDEX |

NEXT |

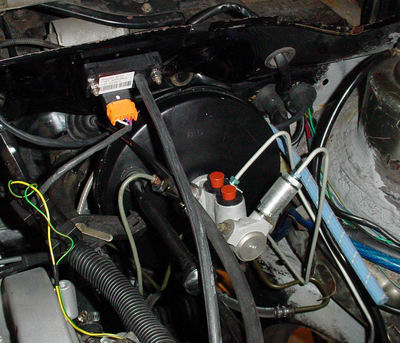

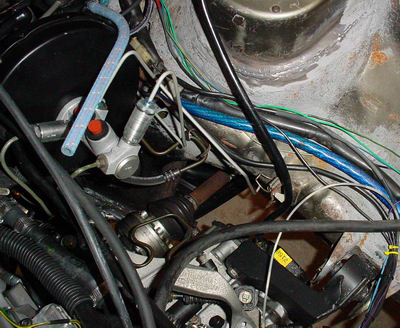

August Wiring Progress |

SHOCKY JR.'S RESTORATION AND UPGRADE ADVENTURE CHRONICLES |

October Swap Related Progress |